Pioneers of printer, scanner and software, 3D Systems developed a software for ProJet® 1200 and ProJet MJP 2500 printers. Making modelling much more free and entertaining, 3D Sprint 2.0 attracted great attention of the users.

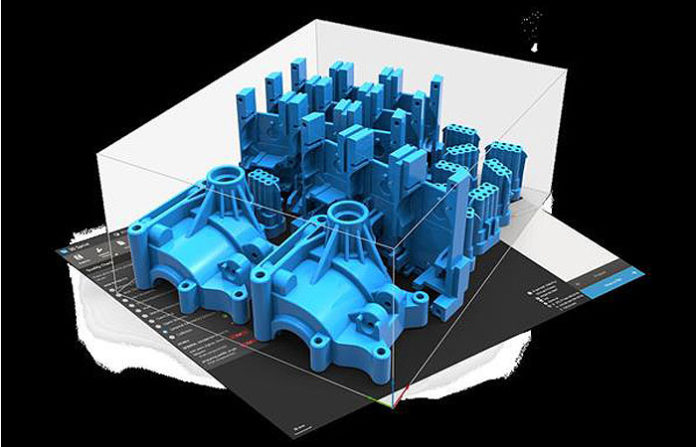

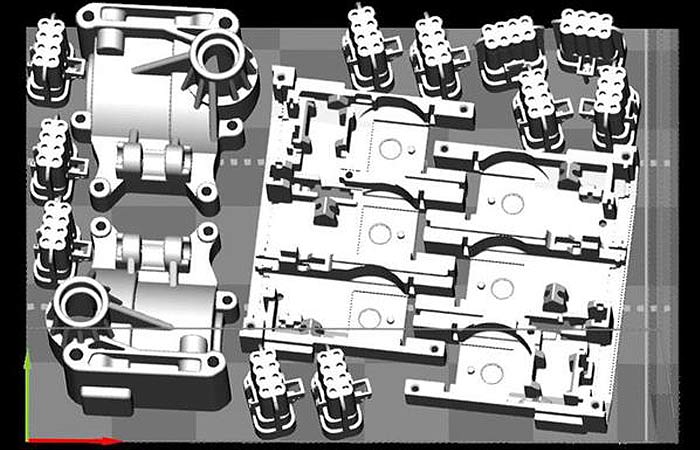

3D Sprint 2.0 delivers a wide range of design tools specific to additive manufacturing that enable users to manipulate, edit and prepare 3D models for printing directly from the software interface. New features within the software allow users to perform advanced operations, including part splitting, cutting and keying; offsetting, shelling and thickening; part grouping, triangle reduction and part quality checks. 3D Systems printer management tools within the platform facilitate firmware updates, system checks and log retrieval to help users efficiently streamline processes while monitoring and managing print queues and materials. 3D Sprint 2.0 accommodates .stl, .obj and .ply file inputs as well as a variety of polygon and neutral CAD formats.

The software currently supports ProJet 1200 and ProJet MJP 2500 series printers, and will begin shipping with these immediately. 3D Systems will announce at a later date when 3D Sprint 2.0 will support their other plastics 3D printers, and also when premium software levels with advanced editing and additional CAD format support will be available. Some of the new software features let users perform advanced operations, like part splitting, offsetting, and part quality checks, and it can accommodate .stl, .obj, and .ply file inputs.

Plastic Production is Faster and Simpler Than Ever

Included with 3D Sprint 2.0 are several 3D printing design tools that enable users to  manipulate, edit, and prepare 3D models for printing directly from the software interface. New features include part splitting, cutting, and keying; offsetting, shelling, and thickening; part grouping; triangle reduction; and part quality checks. 3D printer management tools within the platform can be used to trigger firmware updates, system checks, and log retrieval to help users efficiently streamline processes.

manipulate, edit, and prepare 3D models for printing directly from the software interface. New features include part splitting, cutting, and keying; offsetting, shelling, and thickening; part grouping; triangle reduction; and part quality checks. 3D printer management tools within the platform can be used to trigger firmware updates, system checks, and log retrieval to help users efficiently streamline processes.

“Our goal with 3D Sprint 2.0 is to make 3D printing in plastic easier and faster than ever before,” commented Ilan Erez, Senior Vice President and General Manager of Software at 3D Systems. “Having a single software platform for 3D Systems’ plastic printers helps our customers achieve greater productivity and improved results.”

“3D Sprint 2.0 is the fastest and most reliable user interface we’ve ever used. Having a single piece of intelligent software that can create estimates on numerous virtual machines makes our operations more nimble, and the level of interoperability sets a new standard for what people will expect from 3D printing interfaces in the future,” said Ian Sayers, 3D Printer and Scanner Sales for Hawk Ridge Systems, a partner of 3D Systems.