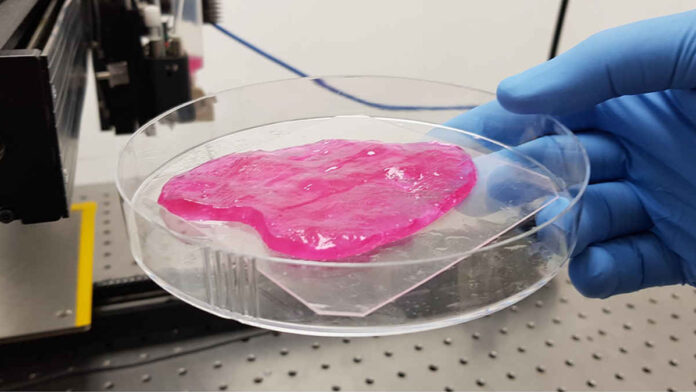

Israeli bioprinting startup company, MeaTech announced that they printed a layer of meat that combines both muscle and fat cells successfully fused. The company used a 3D printing machine customized in its own laboratories for tissue making, in the experiment called “Project Carpaccio”. The experiment gets its name from the resemblance to thin sliced meat. Stating that they are ahead of the schedule, MeaTech explained that their next goal is to print a quarter-pound steak.

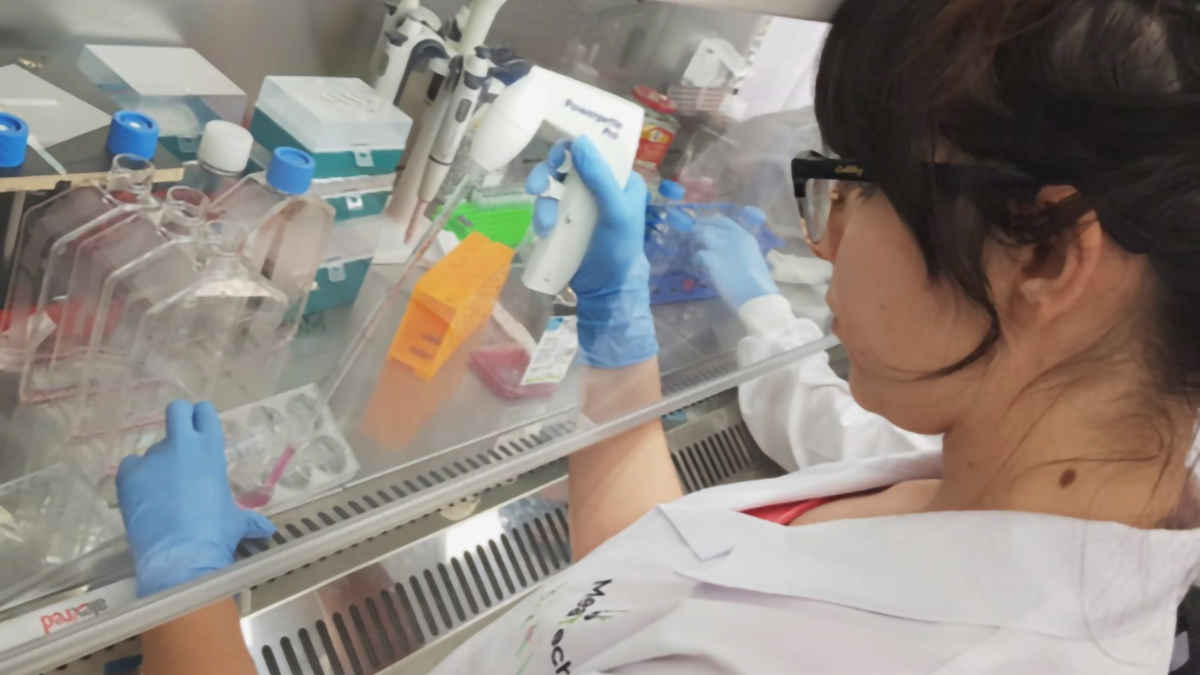

Founded in 2018, Meatech explains their aim is to create alternative foods without harming animals. The company recently announced that it produced a thin sliced meat with muscle and fat cells obtained from stem cells within the scope of the Carpaccio Project. MeaTech’s Chairman, Steven H. Lavin stated that completing this significant milestone earlier than anticipated was a significant technological achievement for MeaTech. Relaying that this brought the company one step closer to developing technology to build slaughter-free meat-growing plants combined with printing technology, Lavin told that this demonstrated the company’s ability to print fat and muscle cells to build tissue.

MeaTech uses its own proprietary 3D printing machine for tissue making

MeaTech developed this successful experiment in 3 key stages. Researchers first obtained a stem cell sample from the umbilical cord taken from cows, etc.; without harming them, to synthesize muscle fibres and fat tissues. Then they reproduced the stem cell and successfully split it into fat and muscle cells. Second, the researchers successfully formulated and manufactured bio-inks designed to print fat and muscle cells to form tissues. Finally, imitating the animal sourced meat tissue, they combined the fat and meat cells to fuse together. In this final stage, MeaTech obtained the animal sourced meat texture and shape using their customized 3D printing machine.

Carpaccio Project also offers solutions to some global problems

CEO and co-founder of MeaTech, Sharon Fima told that this was another step on the path to meeting the company’s vision of; building a plant for the growing and manufacturing of 3D printed cuts of meat; without needing to slaughter or harm any animals. Fima also stated that this is a technology; which could dramatically reduce air pollution, loss of energy sources; and the loss of vast areas currently used for raising livestock for slaughter.