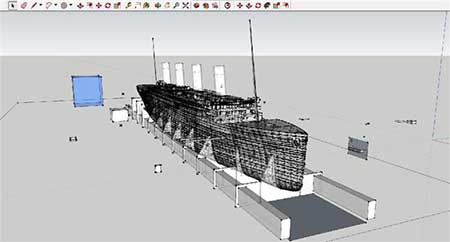

3D printing is a very entertaining platform where creativity meets technology. In social media, we encounter with various products of makers. Being a ship equipment manufacturer, Bernie has carried out one of such projects. Bernie is now printing a four metres long Titanic ship that he was a fan of.

The founder of BernCo a ship equipment provider, Bernie is making the exact replica of Titanic with 3D printing. The project levels up the ‘hobbyist’ 3D printing as a very time consuming and extensive work.

Bernie himself is an ex-navy marine technician, qualified in hyperbaric engineering. Like so many others, he became absolutely mesmerized by the tragic tale of the Titanic. The largest ship in the world at the time of its making, it sunk on its maiden voyage in 1912 after hitting an iceberg. As Bernie recalls, he has been fascinated with the ship since he was a young kid. “I was in my first week of Kindergarten in 1991 when we had our first excursion to the school library. I remember pulling a book out of the shelf and seeing this giant ship helplessly suspending its propellers high into the night sky. Unlike most people, it wasn’t the sinking of the ship that captivated me. It was the size!” he remembers.

So far, the model thus contains up to 30 kg of PLA, and Bernie was fortunate enough to find help from his suppliers 3dprintingshop.com.au. They were so impressed with this gargantuan undertaking, that they donated 25 spools of filament to the cause. “Since using their high purity PLA, I have not had a single print failure due to plastic temperatures or warping through the whole build of this model and several others. When printing so many very large builds, a single print failure can mean an entire spool of waste,” he says of the filament.

their high purity PLA, I have not had a single print failure due to plastic temperatures or warping through the whole build of this model and several others. When printing so many very large builds, a single print failure can mean an entire spool of waste,” he says of the filament.