3D printers are devices that developed with high technology but very accessible. Especially printing with a desktop device is as easy as pressing a button. However most FDM printers don’t have automatic calibration feature which can be problem for some users. Focusing on this issue, Roboze offers a practical solution to 3D lovers.

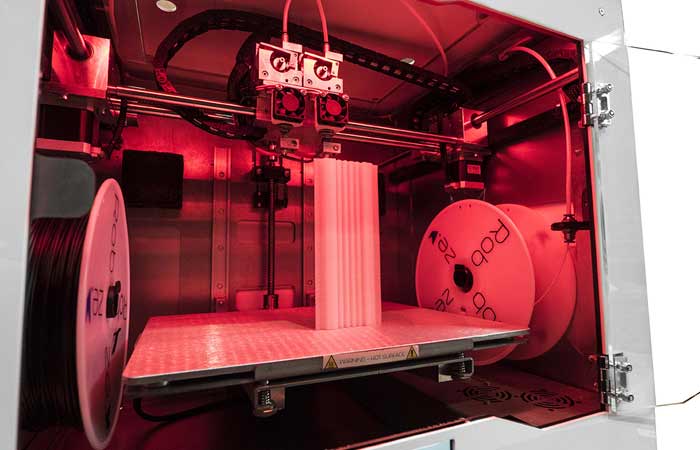

Roboze One +400 is equipped with proprietary firmware and electronics designed to express full mechatronic potential and safely reach very high extrusion temperatures. Roboze One+400 can employ up to 12 different materials. These include PEEK, PEI and Carbon PA, which are considered very important for both the industrial and medical sectors. Furthermore, thanks to the support material on a second extruder it is also possible to build shapes that are more complex, with more challenging geometries. This combines into a one-of-a-kind solution for advanced applications in Medical, Aerospace, Military & Defense, Automotive and other sectors of manufacturing.

“By enabling the use of advanced materials, we offer users a powerful yet affordable solution, together with the advantages of an ‘easy-to-use’ desktop 3D printer. This will open up a wide range of new possibilities, especially for SME’s for a variety of applications in several different industries requiring only a limited amount of investments,” said Alessio Lorusso, CEO, Roboze.

With the One+400, Roboze is introducing the next level of 3D printing technology, based on the summation of elements which are expression of high quality, accuracy and reliability, setting a new standard in the industry.