3D technology made many significant time and cost savings in many aspects. Now it is time for entering the Guiness World Records Book! Some 3D productions take place in the book whose this year edition’s work has started. Being in the book with the tallest guy in the world project of Backface 3D printing continues its records with successful prints.

The number of techniques for making large-scale parts with 3D printing and additive manufacturing is growing along with part size. We’ve reported on several, including Sciaky’s, the Stratasys Infinite Build demonstrator , and the Big Area Additive Manufacturing (BAAM) machine developed by Oak Ridge National Laboratory (ORNL), used to 3D print the composite Strati car at IMTS 2014.

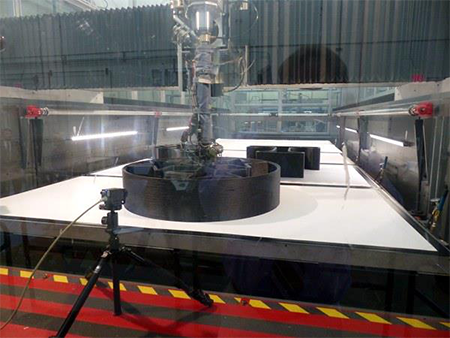

The biggest of all, according to Guinness World Records, is a 3D-printed trim and drill tool that measures 17.5 ft x 5.5 ft x 1.5 ft. It now holds the world record for the largest solid 3D-printed item. Researchers at ORNL built the tool to be evaluated by Boeing for use in constructing the aircraft leader’s 777X passenger jet.

“The existing, more expensive metallic tooling option we currently use comes from a supplier and typically takes three months to manufacture using conventional techniques,” said Leo Christodoulou, Boeing’s director of structures and materials. “Additively manufactured tools, such as the 777X wing trim tool, will save energy, time, labor and production cost and are part of our overall strategy to apply 3D printing technology in key production areas.”