Industrial additive manufacturing market welcomes a whole new printing system. CNC machinery manufacturer, Thermwood Corporation introduced Large Scale Additive Manufacturing(LSAM) raises manufacturing volume and speed.

Indiana USA based CNC machinery manufacturer, Thermwood presented its first 3D printing solution. Foreseen to be very effective in industrial manufacturing, LSAM offers almost end user product quality with two step manufacturing process.

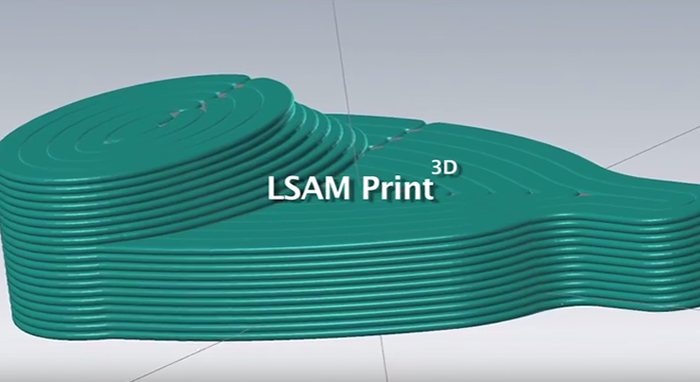

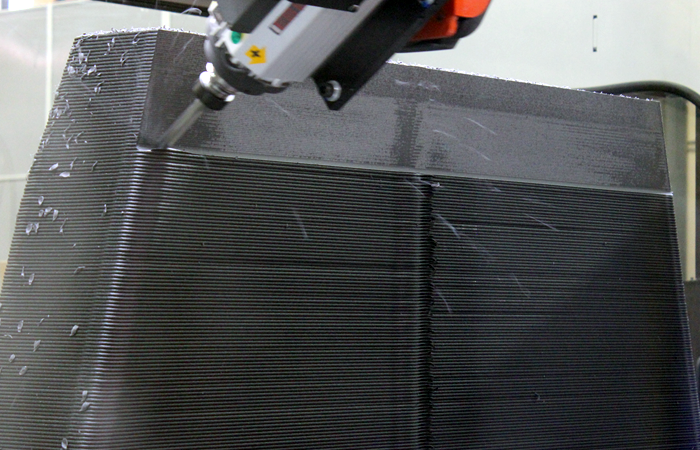

The philosophy behind the new LSAM machines is clear; 3D printing ‘additive’ and CNC milling ‘subtractive’ can be combined to create accurate, large-scale parts far more effectively than any single manufacturing technique. As such, each new LSAM machine includes both a 3D printing gantry and a second trim gantry that is actually a five-axis CNC router. Both gantries operate over the entire table surface, meaning all necessary functions for part production are carried out on the same machine.

The 3D printing gantry of the new machines features an advanced, vertically mounted PH Series print head, made by Thermwood, which melts and meters the polymer 3D printing material. The print head can process filled thermoplastic composite materials at temperatures up to 343°C while its triple servo design purportedly enables accurate and high-output printing, as well as providing the ability to change bead dimensions while printing. The design also produces better layer adhesion and gap-free printed structures.