Drawing interest of the market with printer, equipment and filament solutions, Leapfrog aims to provide energy and cost saving to the users by adding automatic shutdown feature to its printers.

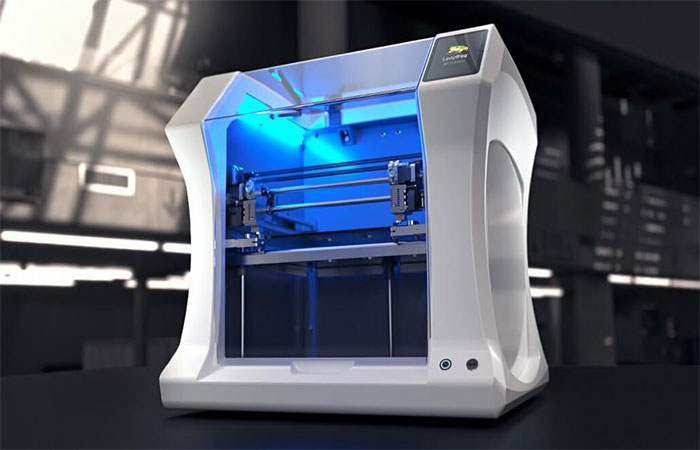

Entering 3D market firstly with Creatr printer and proving its quality with dual extruder Bolt, Leapfrog comes to the forefront with product development projects. Providing automatic shutdown to its printers, the company goals for energy and cost savings.

Auto shutdown is Leapfrog’s contribution towards helping reduce the significant amount of  electricity wasted by 3D printers whilst on standby. The majority of 3D printers take several hours to produce a print and once finished, are often left on standby overnight because the operator has gone home. The feature has been incorporated by the Dutch company to reduce the over-usage of electricity when its machines are not operating. Typically, 3D printers left on standby, waste a significant amount of electrical energy. Worldwide, there is believed to be over a million 3D printers installed. Most 3D printers need several hours to complete a single print, and thus are usually left on standby overnight with no operator nearby.

electricity wasted by 3D printers whilst on standby. The majority of 3D printers take several hours to produce a print and once finished, are often left on standby overnight because the operator has gone home. The feature has been incorporated by the Dutch company to reduce the over-usage of electricity when its machines are not operating. Typically, 3D printers left on standby, waste a significant amount of electrical energy. Worldwide, there is believed to be over a million 3D printers installed. Most 3D printers need several hours to complete a single print, and thus are usually left on standby overnight with no operator nearby.

Thusly this feature will be added to all Leapfrog printers with the latest user interface. This small but blockbuster venture will influence 3D market for producing eco-friendly printers that offers cost and energy saving.

“As the installed base of 3D printers continues to grow, adding an automatic shutdown feature to new and existing machines has the potential to save a tremendous amount of energy,” said Sander Adam, CEO of Leapfrog 3D Printers. “We hope that this practice will be adopted by all our competitors in order to make our industry more sustainable.”