Being in the agenda of FDM printers market, 6 axis 3D printer provides advantages during and post printing.

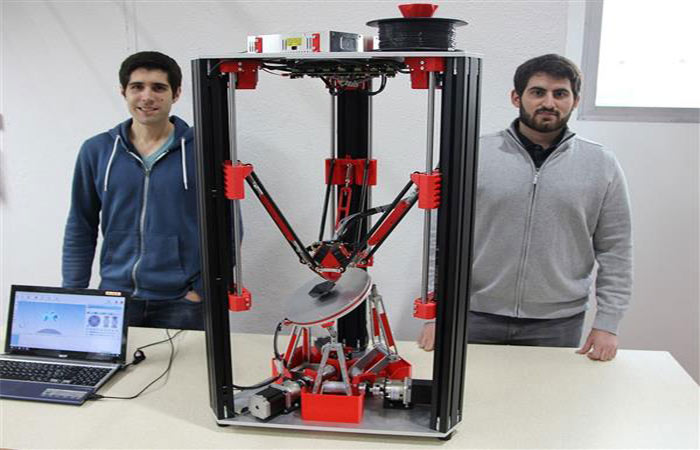

Students from Zurich University of Applied Sciences (ZHAW) in Switzerland made a significant innovation. Developing an FDM printer with six axis, Oliver Tolar and Deniz Herrman offers solutions to the main problems in FDM (Fused Deposition Modelling) printing technique.

The additional axes allow the printer to create more elaborate objects. Especially when it comes to models with odd curvatures and overhangs. By tilting the bed, the printer manages to pull off difficult geometric shapes. In essence, the printer has 3 axes that control the print head, while the other 3 move the bed to aid in areas that require the shape to be contorted.

It bears reminding that the printer is not yet past the prototyping stage. The students are currently working on the next prototype. They hope to improve on the design in significant ways. The next obstacle is to get the print bed to move in conjunction with the print head. This will enable the printer to perform a continuous print.

Although the six-axis 3D printer sounds pretty impressive, there is one important caveat to the project. With limited time and resources to develop the 3D printer, Tolar and Herrmann were not able to develop software capable of simultaneously moving the print bed and print head.