3D print service and material provider ALT LLC, points out a significant problems of 3D aterial consumption with recyclable materials. Looking for support in Indiegogo, the company aims an eco-friendly manufacturing.

Reaching to the customer with CAD, 3D printing and material solutions, Santa Barbara USA-based ALT LLC draw interest with its pioneer venture. In that sense producing a filament with recycled plastic wastes, the firm presents this venture at Indiegogo platform

In United States, only 9% of post-consumer plastic (2.8 million tons) was recycled in 2012 . The remaining 32 million tons were discarded. California lawmakers have set a new target for the state to recycle 75% of waste by 2020 as per the new law AB 341. ALT wants to see manufacturing in California revolutionized. Their goal is to reduce the amount of plastic waste that ends up in landfills, waterways and ultimately, our oceans by sourcing the plastic waste used to make their filament from local California waste collection facilities. ALT hopes their initiative inspires other local engineering firms to adopt green practices.

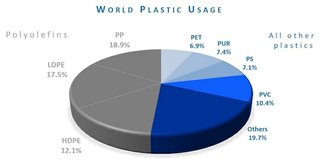

ALT’s recycled 3D printing filament is produced in house and made from a class of polymerscalled Polyolefins. This includes common plastics such as Polypropylene (PP), Low-Density Polyethylene (LDPE), and High-Density Polyethylene (HDPE) used to make plastic bags, milk jugs, bottle caps, and other short-lived products that are discarded within a year of manufacture.

Polyolefins have excellent properties for use in many applications, which makes them the perfect material for 3D printing. Both high and low-density polyethylene are desirable due to their flexibility, toughness, ability to withstand high temperatures and their impact, moisture and chemical resistance. Polypropylene is similar, but has a higher thermal resistance enabling it to withstand the heat of an autoclave. Together, polyolefins account for nearly half of the plastic being used on the planet today.

While several companies use plastic water bottles to make PET 3D printing filament, ALT wants to tackle the plastic that makes up the largest amount waste and that rarely gets recycled. Supporting this campaign will help ALT produce their high performance recycled 3D printing filaments and bring them to market at an affordable price significantly reducing waste and making an impact on the environment.