The materials used in additive manufacturing, are very important for the end-product. Determining product’s quality and surface resolution, these materials show variety in terms of aim of use and place. Developed by a sculpter called Adam Beane, Cx5 filament presents users a very effective production phrase.

3D material market develops just as printer and software segments. While the available materials improve with innovations, new members expand the product range. The last example of these is the innovative filament; Cx5 which was presented in Kickstarter. Developed by a sculptor Adam Beane, this filament can easily be shaped.

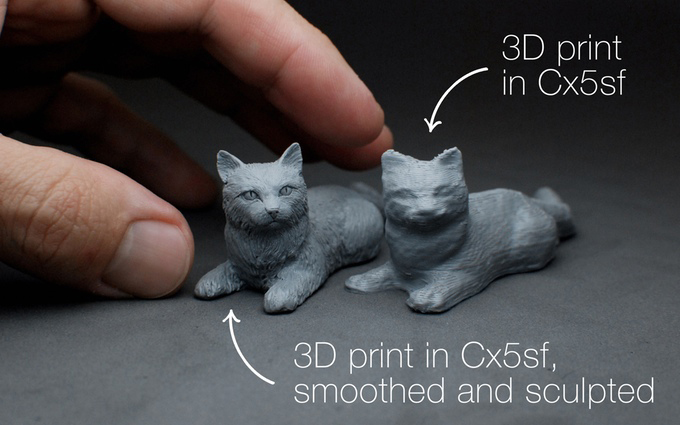

Cx5 sculptable 3D printing filament is the latest product developed by Adam Beane Industries, a company known for its other innovative sculpting products. The filament, undoubtedly one of their most exciting products, will allow makers to combine their digital design and sculpting skills with their hand-sculpting and finishing skills. In other words, makers will be able to smooth, modify, carve, and detail their 3D prints right off the print bed. That means no more toiling for hours trying to get FDM print lines off of a print and no more settling for vaguely detailed pieces.

A number of notable artists and designers have expressed their excitement about the new sculptable 3D printing filament, noting its virtually limitless creative possibilities. Ryan Kingslien, a fine artist and a project manager for ZBrush, said: “To be able to pour your heart into the computer and then be able to print and pour your heart back into the clay…to bring your signature, your life to it, this is a game-changer. This is an amazing moment for us sculptors.”

The crowdfunding campaign of the product is seeking to raise $75,000. So far, it has already raised nearly $8,400, a number which is rising quickly.