Starting with giant brands like Nike, Under Armour, 3D trend continues to influence all shoe and garment sector. Italian based Footwear Polytechnic will go on its service with RepRap solutions.

One of the segments where new generation technologies created reactions, garment and design sectors will now have a unique platform with 3D technologies. Providing both saving and easiness, this technology now stepped into Italian footwear sector with Footwear Polytechnic’s center fo excellence FFLab. Performing works on shoe manufacturing, this centre will witness RepRap printer and 3D scanner runnings.

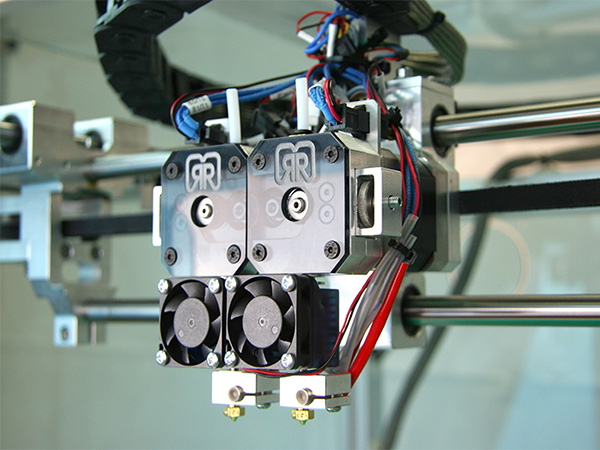

In the laboratory of the Polytechnic, footwear components are designed in an electronic format with the 3D CAD technology and then printed in 3D with the 3D printer German RepRap x400 PRO V3, provided by 3DZ. The other method used is reverse engineering, which allows to get, through a 3D scan, the physical model of a CAD file, ready to be edited as needed and then printed. These new technologies, which can be enjoyed by FFLab visitors, allow the Footwear Polytechnic to meet the demands and needs of the companies that cater to the institute.

format with the 3D CAD technology and then printed in 3D with the 3D printer German RepRap x400 PRO V3, provided by 3DZ. The other method used is reverse engineering, which allows to get, through a 3D scan, the physical model of a CAD file, ready to be edited as needed and then printed. These new technologies, which can be enjoyed by FFLab visitors, allow the Footwear Polytechnic to meet the demands and needs of the companies that cater to the institute.

The use of new scanning and 3D printing technologies enabled companies to create structures, accessories and other components impossible to realize with their equipment, with a greater precision. Users can directly provide the STL file suitable for printing, already created within the company (like a heel, an accessory, a sole), or providing the physical object, such as a shape, in order to make it scanned, rebuild in 3D or even modified making some changes. It will be then printed in 3D with the given material.

Furthermore, 3DZ collaborates in the training course on “Rapid Prototyping and Reverse Engineering” aimed at people employed in the footwear industry. Lessons are taught by Eng. Alessandro Favaro from 3DZ Treviso and Prof. Matteo Turchetto of the University of Padua, which deals with projects on 3D scanning. More free seminars on 3D printing and Reverse Engineering were launched in October at FFLab.

“We have turned to 3DZ for the prior knowledge of the capabilities of this company, the equipment quality, the availability and excellent service. Thanks to their on-site training, two people of the staff have been instructed about the proper use of the new equipment”, summarizes Alice Marcato.