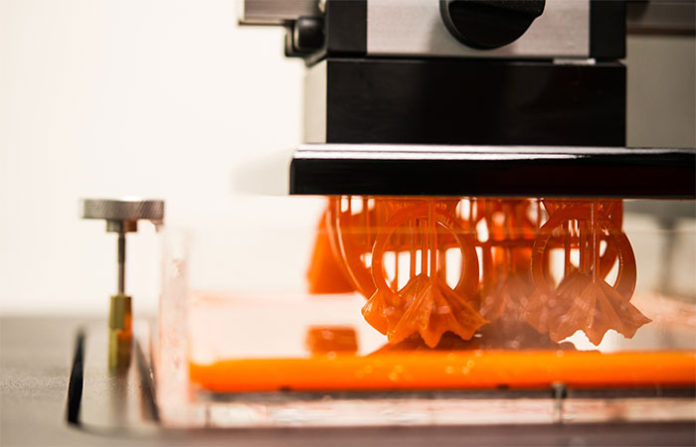

Bringing speed and durableness to 3D printing technology, Ackuray provides one solutions to various applications with A135 printer offering DLP technique.

Offering a complete solution partnership with 3D printer, equipment and materials, Ackuretta Technologies continues to expand its product range. Carrying high technology printing into different application areas with A135 printer, the firm also gained interest with material  options.

options.

The Ackuray A135 provides a build envelop of 135 x 76 x 130 mm with 70 micron resolution on X and Y. It features a closed-loop brushless servo control of the Z-axis which permits resolutions of up to 1 µm increments making the Ackuray unparalleled in accuracy. The ingenious design of the system also has very few moving parts, making it highly reliable and easy to operate.

“The A135 embodies the innovation and value that Ackuretta has set out to achieve in order to revolutionize the additive manufacturing industry,” said Ayush Bagla, Managing Director of Ackuretta Technologies. “By incorporating DLP technology in a flexible, high-precision 3D printer, we are set to provide the product manufacturing industry with the speed and accuracy necessary to deploy 3D printing in viable business model.”

The A135 utilizes Materialise Visualizer software which opens a wide range of applications for DLP 3D printing. This highly functional, reliable software platform offers a streamlined user experience with great precision and customization abilities. As part of the A135 launch, Ackuretta is introducing 4 different resins engineered specifically for applications in jewellery, dentistry, medical, prototyping and production. These include four biocompatible materials, as well as materials for casting and modelling.