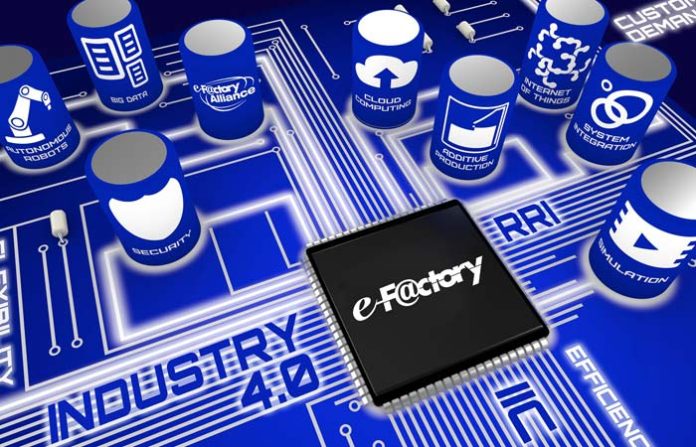

The award winning e-F@ctory concept for digital transformation of enterprises from Mitsubishi Electric.

Hartmut Pütz, President Factory Automation EMEA at Mitsubishi Electric Europe, focused on the digital transformation of industry. Pütz stated that end users’ desire to reach customized products with price ranges similar to those of standard products increased flexibility needs in production and said that at this point the smart factories start to come into being. Pütz emphasized that Industry 4.0 and the fact that the number of devices connected to the Internet of Things (IoT), which is the basis of smart factories, is predicted to increase exponentially over the next few years, and also gave information about Mitsubishi Electric’s award winning e-F@ctory concept launched for digital transformation of enterprises.

Industry 4.0 which leads a rapid change in manufacturing industry, brings the transformation to a fully digitised manufacturing. Hartmut Pütz, President Factory Automation EMEA at Mitsubishi Electric Europe who emphasized that end users increasingly expect more product variety and customisation, but at a similar price point and stated that the changing demands of the production processes has a great impact on the development.

Hartmut Pütz drew the attention that the level of flexibility in manufacturing increaes and added that “For example, with the rise of online ordering, the link from a sale to a machine tool or a robot altering its work pattern is closer than ever. To satisfy this demand of consumers suppliers require the highest levels of flexibility from their manufacturers throughout the supply chain. Therefore manufacturers have to react very quickly, changing production numbers for individual items on the fly. This is where the’smart factory’ starts to come into being. As Mitsubishi Electric, we bring all of our activities related to the digital transformation of enterprises and the development of smart factories under our e-F@ctory concept.”

Pütz stated that within the framework of this concept, Mitsubishi Electric designed e-F@ctory Alliance encompassing a worldwide active network of cooperating companies and said that “The network brings together manufacturers of industrial components as well as specialist system integrators and software providers and these partner companies collaborate at an individual level to offer flexible, optimised solutions.”

Minimum operation cost, maximum production performance

Pütz stated that one of the great examples of the e-F@ctory Alliance working toward delivering proven solutions to the requirements of Industry 4.0 challenges was performed at Mitsubishi HiTec Paper Europe GmbH in Bielefeld, Germany and explained that “In the said company, a more holistic approach to predictive maintenance has been achieved by implementing a Smart Condition Monitoring solution developed in cooperation with FAGSchaeffler. This solution allows a whole range of parameters from the machines and its ancillary parts to be monitored. That data is then used to analyse the condition of individual components as well as the health of the individual machine and of the wider plant. The information gained from the system includes maintenance recommendations. Thus, the solution has created a new working methodology, drastically reducing unplanned downtime and the risk of subsequent damage. Overall, the result is vastly improved predictive maintenance, optimised asset lifecycle management and production, while reducing total operating costs.”

Award to e-F@ctory concept

Pütz stated that e-F@ctory concept of Mitsubishi Electric has also been recognised by leading initiatives and organisations and added that “Our digital factory concept was awarded the Best Practise Award in “Industrial Internet of Things in Factory Automation” from Frost & Sullivan and the “Strategic Point of Light Partners” award issued by the Taiwanese government.

The number of devices connected with IoT will increase exponentially

Pütz stated that when talking about Industry 4.0, the Internet of Things (IoT) is inevitably a key theme as well and added that recent estimates already put the number of devices that are connected through the IoT will increase exponentially, “Combine that prediction with the amount of data that is being generated and processed by a more connected factory, and it is easy to see why companies’ IT infrastructure needs to change”, and highlighted the importance of cloud-based data storage and processing services at this point.

Technology that integrates data, people, processes and systems

Pütz, by explaining businesses are increasingly using cloud services not simply to store large volumes of data, but also to perform analytics tasks, added that “Processing the data means deriving trend information and presenting users with customised dashboards. The intelligence gained can be used to improve overall plant performance and asset management.”

Pütz inform that Mitsubishi Electric has developed solutions that support both of these complementary IoT approaches and added that, “Our company offers simple and secure access to a range of different cloud services. The remote devices providing the creation of a numerous information and those are linked over standard open protocols that can be seen as the key to forming a digital nervous system within businesses. The networked digital data is then combined into bidirectional systems to integrate data, people, processes and systems for better decision making.”

Project that saves millions of dollars in Intel

Pütz explained that within the context of the Internet of Things; they have realised a project together with Intel® and added that the company is using an IoT gateway from Mitsubishi Electric to aggregate and securely input data into a big data analytics server. Pütz stated that for Intel®, this pilot is forecast to save millions of dollars annually.