Cincinnati Incorporated and New Valence Robotics offers an affordable and fast solution for prototyping with SAAM system.

3D printing’s industrial development continues. Being a pioneer in that sense, Cincinnati Incorporated started working for small productions. Developing SAAM system for these type of productions, the company aims to attract small and medium size manufacturers.

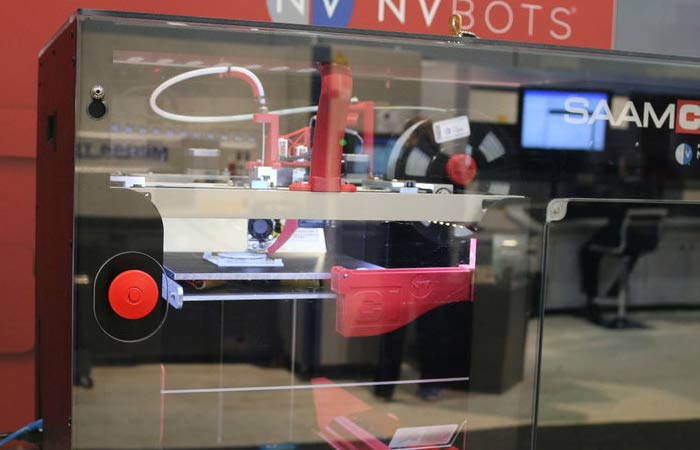

Designed as a complement to CI’s BAAM (Big Area Additive Manufacturing), the system allows designers to prove-out part designs while saving material and time. Once the design has been validated for form and functionality on SAAM, the same CAD files are leveraged to produce larger full-scale parts on BAAM.

The SAAM system offers automated part removal and is paired with NVCloud software that allows users to print parts anytime, from any cloud-connected device – while providing administrators with full control of workflows typical in a shared-use scenario.

In addition to prototyping parts for the BAAM system, the SAAM is also well equipped for simulations. As Chris Haid, Co-Founder of NVBOTS explained, “We can simulate any type of part with the SAAM. The same CAD file we use for the plastic prototype can be sent to a laser, a press brake, or a shear for metal fabrication. It dramatically reduces waste in the design process and allows shops to accelerate moving to the production phase.”