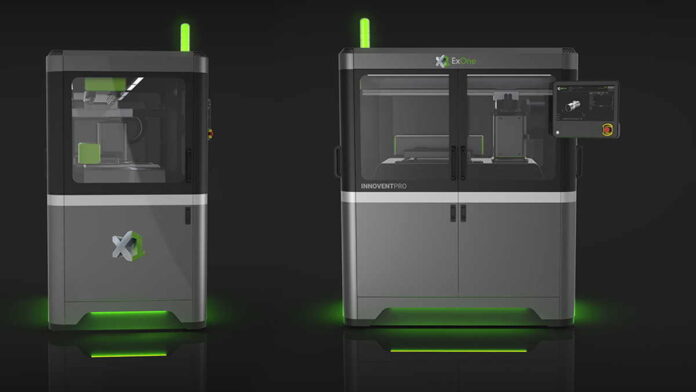

One of the leading companies in industrial sand and metal 3D printing machines using binder jetting technology, ExOne made the concept presentation of the InnoventPro. A preview of the world’s most advanced entry-level binder jetting system for printing metals, ceramics and composites; InnoventPro will be a major upgrade of the Innovent+, the world’s best-selling metal binder jetting system since 2016. In addition, it has been announced that Siemens Digital Industries will take part in the production version of the machine, which will be announced in the second half of 2021, as an Industry 4.0 cooperation partner.

A major update of Innovent+, the system is aimed at academics, researchers, and a full spectrum of manufacturers; from machine and MIM shops to high-volume producers, who want to produce metal parts quickly, affordably and sustainably. ExOne CEO, John Hartner stated that customers around the world already love the Innovent+; and based on their feedback, they are going to give them an updated entry-level system that’s bigger, faster and smarter than ever. In addition, the company announced that they would collaborate with Siemens in Industry 4.0 in the advanced stages.

The new metal 3D printing machine concept offers an all-new functionality in binder jetting

The new InnoventPro includes the same recirculating printhead modules used on the X1 25Pro and X1 160Pro metal 3D printers, allowing users to easily scale up from R&D to high-volume production. The updated printhead lowers the cost per piece with more than triple print speeds; while also allowing ExOne’s pioneering move to offer particulate binders as an option on a commercial binder jetting system. The ExOne research team has been 3D printing a variety of nanoparticles suspended in its binders for years.

InnoventPro offers two new size options, a 3 litre and a 5 litre, with print speeds exceeding 700 cc/hour. However, the updated system gives the option to 3D print a new class of patented NanoFuse binders embedded with nanoparticles to improve part quality and simplify sintering; providing a all-new functionality in binder jetting. In addition, an incentive program for the InnoventPro will be offered to customers; who buy an Innovent+ prior to commercial availability of the new system. Standing out with all these features, InnoventPro rounds out ExOne’s full family of production metal binder jetting systems and accessories; which now includes the X1D1 automated guided vehicle for Industry 4.0 operations.

It opens new doors in binder jetting

ExOne Chief Technology Officer and Vice President, New Markets, Rick Lucas said; “Just as the current Innovent+ served as the proving ground for our patented Triple ACT system”. Stating that now it delivers industry-leading quality in metal binder jetting; the InnoventPro would offer ground-breaking new features in a commercial system; Lucas told that their patented approach to 3D printing particulate inks in a print bed is opening new doors in binder jetting.