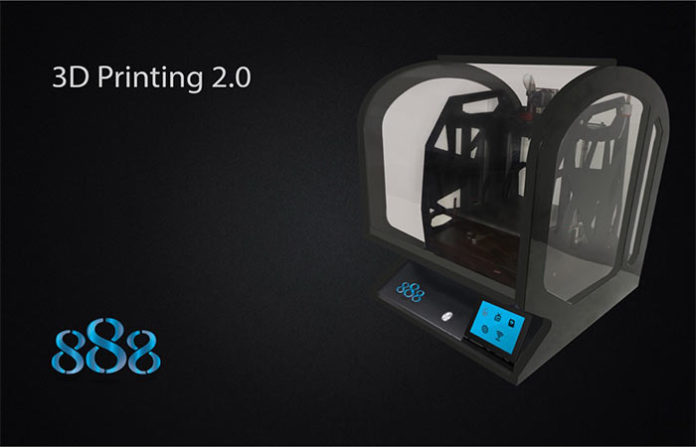

AONIQ, an Australian based company providing state of the art 3D printing technology to a wide range of industries, has designed 888 printer provides advantages in various aspects.

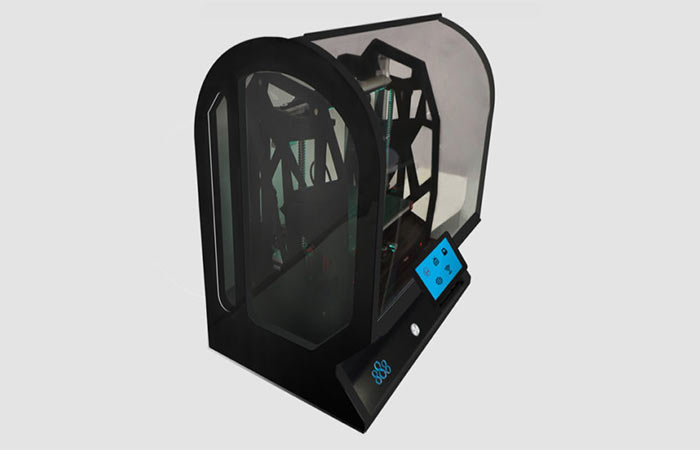

888 is a state-of-the-art 3D printer capable of printing with the AONIQ PVC filament. Major advancement to other FDM/FFF 3D printers is the push release print head on the 888 which allows seamless swapping between materials. There is no need to clean the head. Run the remove filament process and once the head cools down press and release to swap the print head.

The print surface is one of the most critical parts for a 3D print and uneven print surface temperature causes adhesion failure. Over 95% of 3D printers require the print surface to be treated prior to starting a print to ensure strong adhesion. The print surface of the 888 is a AONIQ designed table which heats evenly across the print surface and keeps it at a stable temperature ensuring strong adhesion of the print to the table surface.

888 is compatible with two of the best software slicers on the market – Simplified3D and Cura. This provides the flexibility to fine tune 3D prints or use the basic setting already set up and start printing like a pro from day one. The system also comes in an enclosure which has been custom designed to provide a safe PVC print operating environment. With its built-in camera in the enclosure, customers can receive on-line real time training and support as well as monitor their print jobs remotely.