Adding one more product to its vast material range, Tethon 3D emphasizes flexible and durable printing with Flexalite used both with SLA and DLP printing.

Serving to the sector with ceramics resin and powder alloys, Tethon 3D will provide solutions to more than one printing techniques with its new material. Stated that it is developed because of the high demand from the customers, Flexalite resin enables high quality manufacturing with both SLA and DLP prints.

“Flexalite was developed in response to consumer demand,” says Karen Linder, President and CEO of Tethon 3D. “For some functional applications -personal wearables for example – the absence of color along with flexibility is highly desirable. Comfort, subtlely and minimalism are important design qualities.”

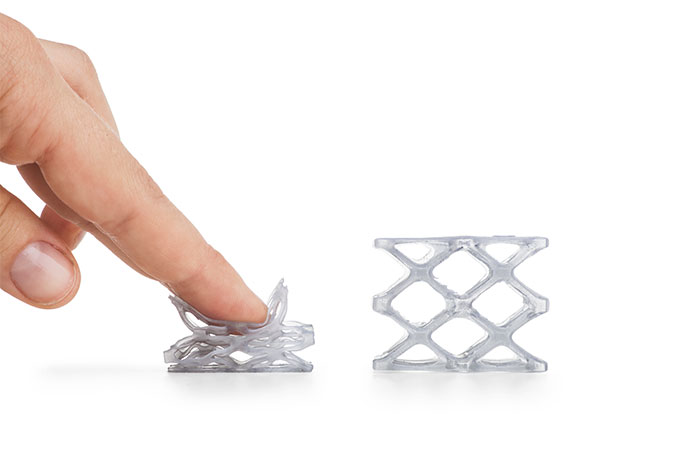

Flexalite is a polymer resin that requires no post processing steps after UV-based 3D printing, other than cleaning and additional UV curing as needed based on the design thickness. It is manufactured at Tethon 3D’s facility in Omaha, Nebraska and is immediately available worldwide in liter bottles by ordering from tethon3d.com.

Additionally, the company provides service in 3D modeling, scanning and ceramic 3D printing, as well as 3D printing educational workshops and a residency program. Tethon 3D holds several patents related to ceramic 3D printing materials, 3D printing processes and 3D printer hardware.

Being a pioneer in additive manufacturing sector with material solutions. Tethon 3D manufactures materials for various applications ranging from SLA, DLP to CLIP and binder jetting technology. Additionally, providing 3D modelling, scanning and ceramic printing education services, the firm informs the sector with educational workshops.