Growing rapidly, 3D ceramics offers opportunity to print in various sizes with the same quality thanks to 3DCeram’s new models.

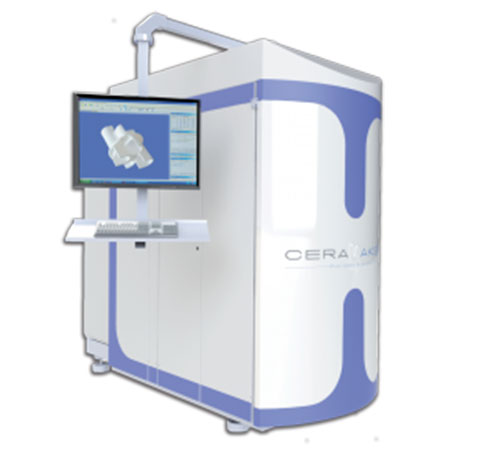

France based 3DCeram aims to offers flexibility to users with various production sizes. Emphasizing quality ceramics printing with Ceramaker 900 that it presented to the market in 2015, the company answers small and wide format printing demands with the newest models Ceramaker 100 and 9100.

These new models including every feature of Ceramaker 900, will offer solutions for bigger or smaller productions. Preferred widely by ceramics manufacturers, sectors using ceramics parts, 3DCeram showed its expertness on these models, as well.

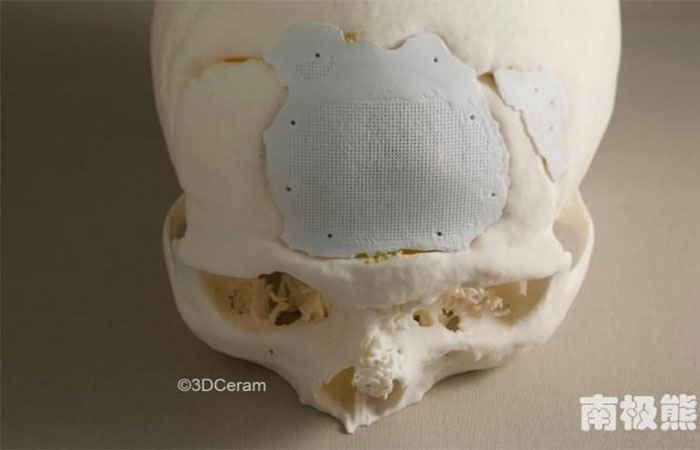

“3DCeram’s 3D ceramic printing solutions are designed for ceramic manufacturers, user-integrators working with ceramic components, luxury goods companies, biomedical firms and almost any industrial group,” Richard Gaignon, the co-director of 3DCeram said. “By launching this new printer, we aim to facilitate and accelerate innovation. Thanks to the powerful technology on board, our clients can unlock their development potential – especially our partners in research institutes.”

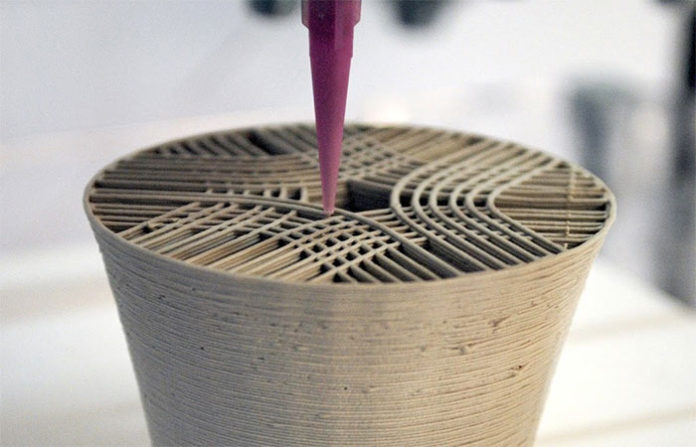

Ceramaker 100 and 9100 use laser printing technology and can print a CAD file directly. Having 00.3 mm. print accuracy, these models can manufacture complex designs with perfect surface quality. The small version Ceramaker 100 was presented to the market and industrial type is foreseen to be released.

After the launch of a smaller machine, 3DCeram will also be offering a printing system for companies wanting to build larger parts. The Ceramaker 9100, an XXL printer with a printing surface of 900 x 900, will be unveiled later this year.