Grabbing attention 3D printing service and distributor, GoPrint3D will present its solution at TCT Show. Stated to collaborate with Roboze, GoPrint has added Roboze solutions in the product range, too.

Being the distributor of many leading brands like Formlabs, Zortrax, Ultimaker and Mcor, GoPrint3D included Roboze to its solutions. In that sense, the distributor will give place Roboze products at TCT Show held between the dates of 28-29 September.

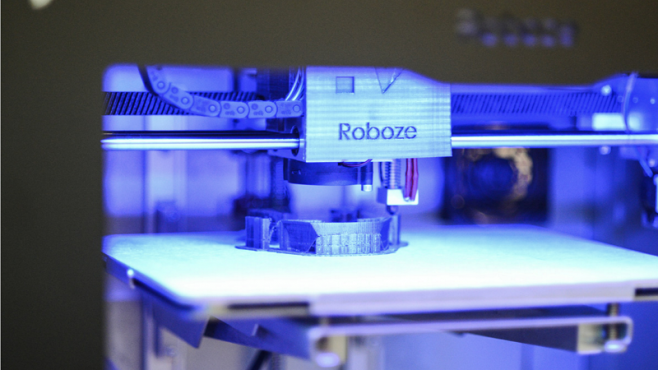

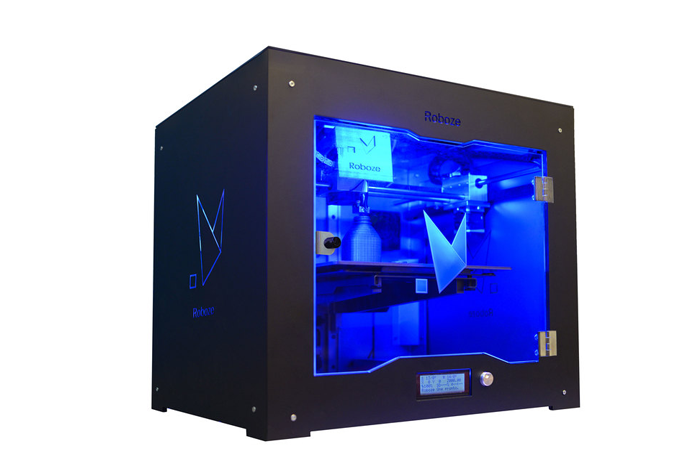

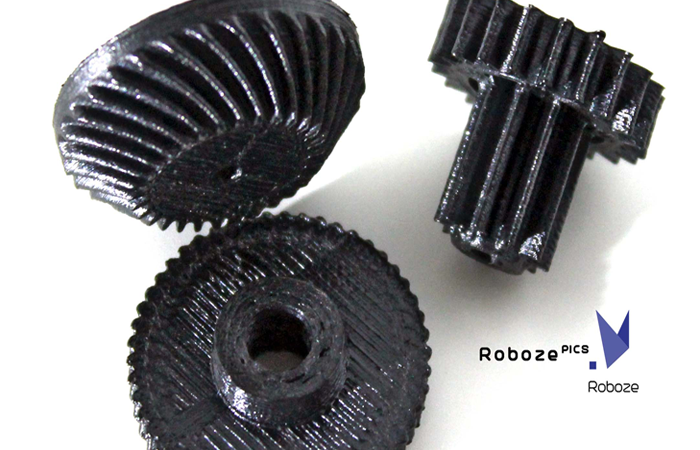

As part of the agreement, GoPrint3D will be focusing on selling the company’s two leading products, Roboze One, a professional desktop 3D printer for functional rapid prototyping applications, and the Roboze One+400, an industrial 3D printer designed for manufacturing with 13 different types of advanced thermoplastics materials including PEEK, PEI and Carbon PA. The Roboze One+400 also benefits from a unique belt-less system which does away with the traditional belt found in most FDM printers in favour of a mechatronic movement system, more commonly found in large CNC machines.

“We are excited to partner with Roboze,” James Blackburn, Director of Sales & Marketing at GoPrint3D commented. “We will be focusing on providing solutions for manufacturers with applications in aerospace and automotive industries.”

“The UK is in the top three most important regions in EMEA which seem to have accelerated in the past few years with regards to the adoption of 3D printing technologies, led by large corporations looking for powerful yet affordable solutions,” Gil Lavi, Roboze’s VP Global Sales & Business Development, explained. “From Automotive, CG & CE, Aerospace to Medical, we see continuous growth in the demand for our products with a focus on PEEK, PEI & CARBON-PA printing capability. These three materials seems to draw the most attention since they are used as a solution to print durable parts for functional testing in extreme environments and also as end use parts for specific applications.”