Being one of the segments where technological developments influenced the most, jewellery sector witnessed another important collaboration. Formlabs’ printer and Gravotech’s software expertness will bring maximum efficiency to jewellery design process.

Presenting professional SLA printing to users with Form printer series, Formlabs continues the enterprises in jewellery segment where 3D printed is used widely. Aiming to provide handier and richer design platform, the company made a software partnership with Gravotech.

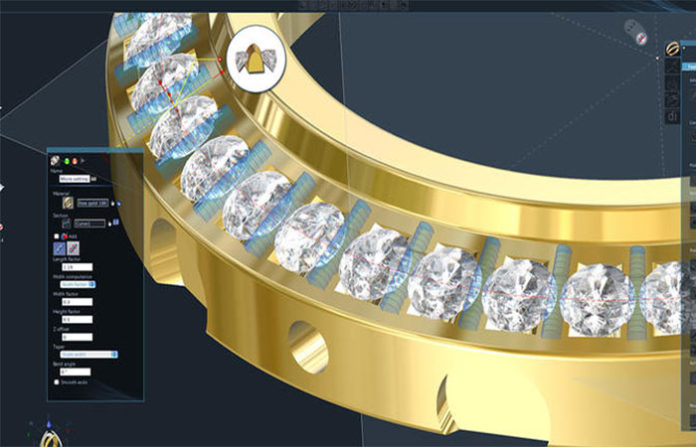

As the go-to jewelry CAD program in the industry, Formlabs’ software integration with 3DESIGN will enable jewelry designers to take any model from the program’s design environment and transfer it to Formlabs’ PreForm software to begin the printing process. Using Formlabs’ new One Click Print functionality, designers can begin printing within minutes.

Now, Formlabs is looking to take advantage of Gravotech’s leading jewellery CAD programme, 3DESIGN. With its powerful free-form sculpting module 3SHAPER and rendering companion DeepImage, 3DESIGN offers jewellers with a competitive software solution. The 3DESIGN software enhances creativity and shorten design and production times.

3DESIGN utilises a clear and intuitive interface, allowing fast learning of 3DESIGN CAD and the production of unique pieces in less time. It also boasts libraries of varied objects, able to be enriched with the user’s own creations. A library of Swarovski elements is also integrated. With multiple file import and export options, the user is able to create pieces in other mechanical CAD software and import them in 3DESIGN to use the professional jewelling features.

Apart from this collaboration, presenting its castable resin specially developed for jewellery applications, the company seems to go on with 3D accessories production.