3D printing techniques and materials are expanded with innovations. Being in the first steps on its 3D journey, glass material will increase its impact with MICRON3DP.

Israel based MICRON3DP prepares to present its glass printing system to the market. Coming to the forefront with print quality and speed, this system is expected to increase glass use in the sector.

MICRON3DP’s glass 3D printer is based on FDM technique which operates at much higher temperatures than its plastic 3D printer counterpart. That is because, in order to bring glass to a melting point, you need temperatures of at least 1000 degrees Celsius. Aside from the extreme temperature, achieving a fine resolution for glass 3D printing had been a distinct challenge for the Israeli glass printing company.

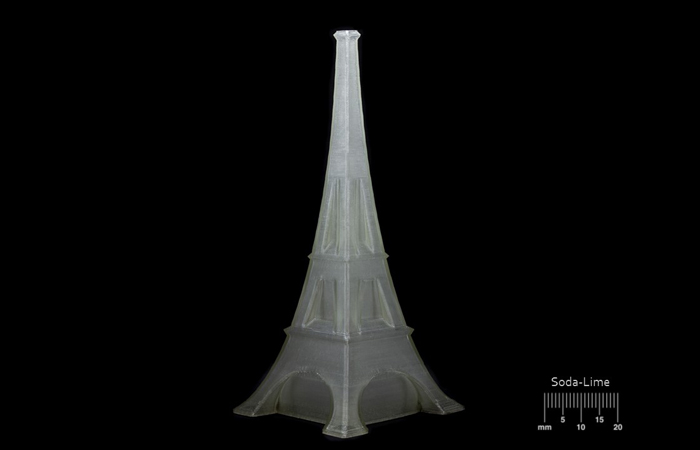

Micron3DP has succeeded in printing ‘soft’ glass at a temperature of 850 degrees Celsius, as well as borosilicate glass at a melting temperature of 1640 degrees Celsius. These are incredibly high temperatures to be working with, but as you can see from the images above and below, they’ve been able to print multiple, rather intricate objects in a variety of different colored glasses. The glass printed in liquid form, in a similar way in which molten thermoplastics are printed on a Cartesian-based machine.

Micron3DP’s R&D Department is experimenting with a new and exciting advanced glass 3D Printing method,” Eran Gal-Or, R&D Manager of Micron3DP explained to 3DPrint.com this morning. “Micron3DP made a successful 3D printing test and although efforts have been made in the past by other companies to print with this medium, this is the first time that glass has been printed in liquid hot form and Micron has accomplished it by means of its innovative way of 3D printing in an extremely hot extruder.”