KULR announced that NASA’s Marshall Space Flight Center (MSFC) has awarded the Company a dual-use technology development agreement to build 3D printed battery systems for manned and robotic space applications. KULR’s passive propagation resistant (PPR) and internal short circuit (ISC) technologies will be used to develop 3D printed battery systems meeting the JSC 20793 Revision D safety standard created by NASA for crewed space missions. Battery packs produced with 3D printing provide many conveniences and advantages in space exploration as well as reducing costs.

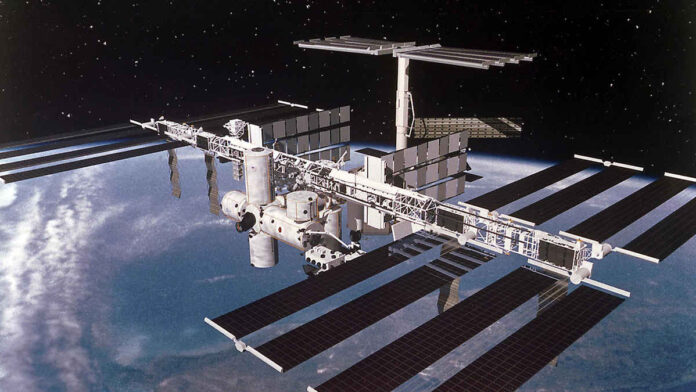

KULR’s PPR solution had demonstrated its efficiency when it was used by NASA to transport and store batteries aboard the International Space Station last year. Now, MSFC’s 3D printing expertise, combined with KULR’s proficiency in designing PPR battery packs, brings the quality of safe battery power systems manufactured in outer space to the pinnacle. The ability to 3D print in space has many advantages, such as allowing for extended missions; and reserving cargo capacity for other valuable items and/or equipment as well as the potential to make human space exploration less costly.

The 3D printed parts are game changer

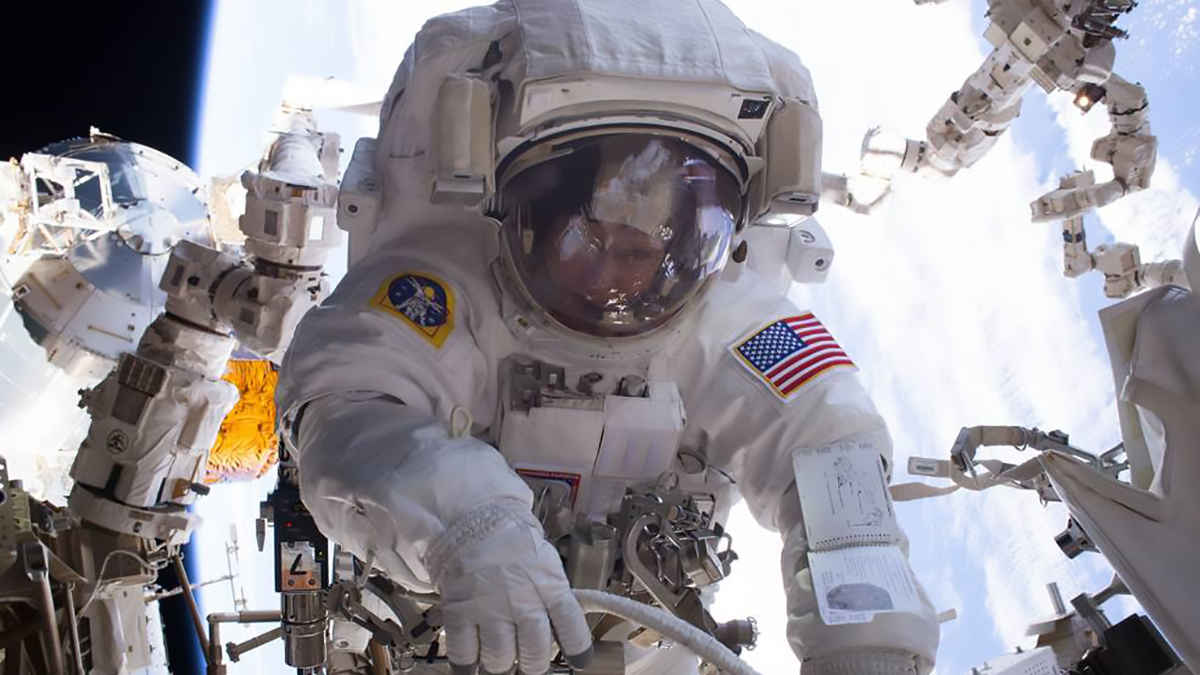

Co-founder and Chief Technology Officer of KULR, Dr. Timothy Knowles said that the optionality to repair and replace battery packs; in space with parts 3D printed in space is a complete game changer. Stating that NASA would build sustainable elements on and around the moon; in preparation for an eventual human mission to Mars about the upcoming Artemis missions; Knowles noted that 3D printing of KULR’s PPR battery design would help lower the costs; associated with battery pack transportation for these missions.

NASA MSFC Deputy Chief Technologist John Carr told that NASA employs highly rigorous assurance and safety standards; especially for their man-rated technologies (with acceptably low risk and suitable for human use). Carr said; “KULR’s PPR design solution for future manned and unmanned space missions is an ideal fit for mass design, flexibility and cost; all the while maintaining this safety rigor through battery risks such as thermal runaway”.

Human Landing System Cross Program Analysis Coordinator, Brandon Lewis explained that through their partnership with KULR; they would now have the incredible ability to build space-optimized battery pack systems in-orbit. Telling that they take the safety of their astronauts very seriously; Lewis stated that KULR’s technologies would enable them to build safer battery packs; that prevent dangerous thermal runaway propagation and protect their most valuable assets.