RUAG deepens cooperation with Oerlikon AM to achieve serial production of 3D printed components for space. Additive manufacturing partnership for space applications. 3D printing will reduce costs by 25 percent and decrease weight by more than 50 percent. Collaboration will accelerate additive manufacturing series production for space components.

Oerlikon (SIX: OERL), a leading technology and engineering group, and RUAG Space, a division of the technology Group RUAG, signed a Memorandum of Understanding, during the Farnborough Airshow to qualify and accelerate series production of 3D printed space components.

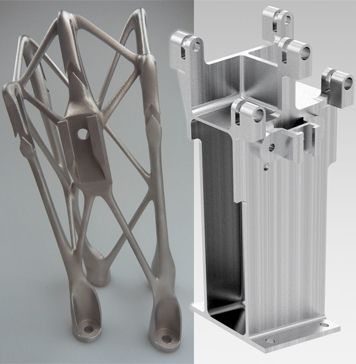

Oerlikon and RUAG Space are already working together on the qualification of a bracket that would be installed on a payload fairing. A new optimized design made possible through additive manufacturing (3D printing) will reduce costs by 25 percent and decrease weight by more than 50 percent, while doubling the stiffness of the bracket. The collaboration on the bracket exemplifies the companies’ strong partnership, which will be deepened further through this initiative.

“Through our ongoing collaboration with RUAG Space, we have identified opportunities to fine-tune the qualification and certification processes, which are crucial in ensuring consistent quality in production,” said Dr. Roland Fischer, CEO, Oerlikon Group. “We are confident, that our materials and additive manufacturing expertise will further grow this important partnership.”

With Oerlikon AM and RUAG, additive manufacturing of space components

Within this cooperation; both companies intend to co-develop processes and standards for the metal-based additive manufacturing of space components; the intention being to establish standards suitable for the European space community to adopt. The partnership also will explore the refinement of existing alloys for the additive manufacturing process; and the development of new metallic materials to unlock future design opportunities.

“We see this partnership as an important step in unleashing the full value of additive manufacturing in the development of new products; that meet the rapidly evolving demands of the space industry”; said Peter Guggenbach, CEO, RUAG Space. “We are working on standardizing additive manufacturing operations for space; and are excited to collaborate with Oerlikon AM to further develop industry-leading standards and processes.”

RUAG Space is the leading supplier of products for the space industry in Europe; and has a growing presence in the United States. RUAG Space has been conducting intensive work on developing; and successfully flying components for spacecraft and launchers using additive manufacturing technology since 2014.