Laser is commonly preferred in 3D printing and other manufacturing techniques. This advantageous alternative is now combined with 3D printing in SafFire.

Joining to Kickstarter, SafFire attracts attention wil its versatility. Bringing both Stereolithography(SLA) and laser engraving solutions together, this printer offers alternative with different pricing.

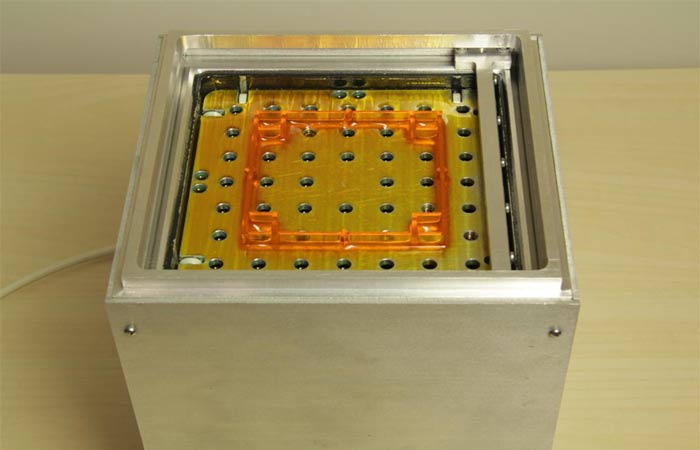

While the SafFire has the potential to be both a laser engraver and 3D printer, customers must choose which add-ons they require at the point of purchase. The base unit is capable of laser engraving wood and paper, but the small (120 x 80 x 80 mm) and large (110 x 110 x 125 mm) 3D printing accessories come as paid extras. This modularity ensures that digital manufacturers only purchase the pieces they need. “The SafFire Laser Engraving System with Small and Large 3D Printing Accessories is a modular tool for jewelers, dentists, makers, and anyone who wants top-quality stereolithography prints or wood engravings at an affordable price,” Matteson said.

The SafFire is versatile not only in its functions, but also in its material compatibility, as it works with virtually any resin that cures at 405nm. Better still, the printer’s 75 micron laser spot allows for tiny positive and negative features to be made in those materials. According to Matteson, the SafFire has advantages over most SLA and DLP 3D printers, with many SLA 3D printers having larger laser spots, and most DLP 3D printers having more “boxy” voxels that can produce a jagged, visually unpleasing finish. Furthermore, the SafFire has relatively few components compared to other SLA 3D printers, making it cheaper and hypothetically more reliable.