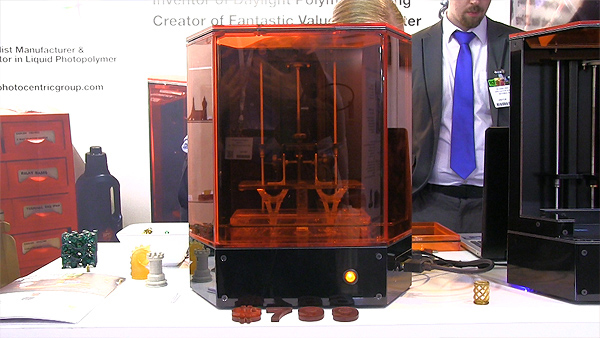

3D printer and material manufacturer Photocentric goes on its innovations. Preparing to present its new Liquid Crystal Pro 3D printer at TCT Show, the firm used its own printing technique for this printer.

With Liquid Crystal Pro 3D the firm have developed a very clever LCD screen-based 3D printing technology called Daylight Polymer Printing, which uses low-cost hardware to realize a very high resin 3D printing resolution. With their smallest 3D printer costing as little as £449 they could have the power to bring resin 3D printing to home users.

As the company explained, they decided to opt for a remarkable concept that harnesses the  power of mass-produced LCD screens, which are widely used in smartphones and other hand-held devices to ensure the highest resolution. As that technology is already well-established and affordable, it is a perfect light source for affordable 3D printing. “The concept is simple – use the daylight emitted from an LCD screen to polymerize resin that is tailored to that wavelength and intensity. All other 3D printers that polymerize resin use a combination of both daylight and UV light at considerably higher intensities,” they say.

power of mass-produced LCD screens, which are widely used in smartphones and other hand-held devices to ensure the highest resolution. As that technology is already well-established and affordable, it is a perfect light source for affordable 3D printing. “The concept is simple – use the daylight emitted from an LCD screen to polymerize resin that is tailored to that wavelength and intensity. All other 3D printers that polymerize resin use a combination of both daylight and UV light at considerably higher intensities,” they say.

The LIQUID CRYSTAL 10” Daylight Polymer has a build area of 200x100x200 mm and the smaller brother has a build area of 60x100x120 mm. Both printers have a layer height of 25 microns. The bigger one costs £699 and the smaller 3D printer costs £449.