One of the pioneers of printing world, Ricoh doesn’t stop its 3D projects, either. Focusing on new materials for its printer AM S5500P, the company collaborated with Solvay.

Entering 3D world with its AM S5500P printer presented at Formnext 2015 for the first time, the company is now focused on material development projects. Working with a material expert Solvay, Ricoh will use the firm’s Sinterline Technyl GB high performace alloys.

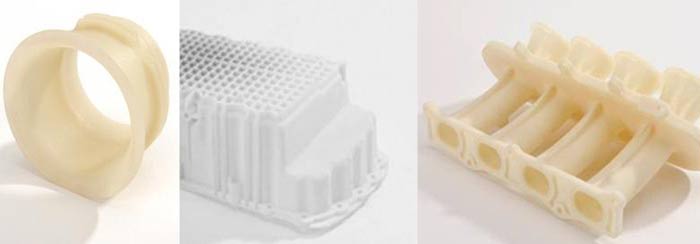

By joining their efforts and long-proven knowledge, Ricoh and Solvay proposes a unique offer to the market, combining RICOH AM S5500P’s extended possibilities, and Sinterline® Technyl® PA6 GB (Glass Beads) high performance powders. RICOH AM S5500P is the largest machine that is able to print Sinterline® Technyl® PA6GB, a material that is of strategic importance in the automotive and aerospace industries. This machine is one of only a few globally able to print higher temperature polyamides. The combination of these two innovative solutions enables manufacturers to create short-runs and functional prototypes with performance comparable to PA6 injection molded parts.

Greg Plowman, Director, European AM Business Group, Ricoh Europe, commented: “The potential of PA6 GB allows us to evolve the range of applications the RICOH AM S5500P can offer to our customers. The intrinsic features of PA6 powders allow functional prototyping and are ideal for small series applications where part performance and durability are essential criteria.”

Ralph Rissé, Sinterline Global Business Development Manager, Solvay Performance Polyamides, added: “Today, speeding up the development process of new applications across a wide range of industries, especially automotive, is crucial. The rapid prototyping of demanding parts that are closer to the final materials used for serial production provides OEMs and tiers an overwhelming design advantage when facing global competition to get products to market.”

added: “Today, speeding up the development process of new applications across a wide range of industries, especially automotive, is crucial. The rapid prototyping of demanding parts that are closer to the final materials used for serial production provides OEMs and tiers an overwhelming design advantage when facing global competition to get products to market.”