One of the attention-grabbing brands of Italy, Roboze showed its versatile solutions at Formnext fair. The company’s booth became center of attention for both professional users and hobbyists.

Attending to Formnext for the second time, Roboze presented its prominent products. Drawing attention with its fast developing, the company proved its power in the market at the fair.

The company in the first edition showed the beta version of the machine and after one year, with cooperation and collaboration from strategic partners in fields of aeronautics, aerospace and automotive, using the company’s technology to implement 3d printing in their manufacturing processes.

“We at Roboze have an intense relationship with the market. We recognized that more than anything else, companies, and professionals in general, needed a comprehensive tool, which gave way to see realized their ideas in a functional way, with special and particular mechanical, thermal or chemical proprieties for each individual “says Ilaria Guicciardini, Roboze Marketing Manager. “Giving an intuitive and fully versatile tool, as well as accessible in the price, was the need that we have recognized and confirmed during the Formnext 2015. The race of digitizing manufacturing with 3D-printing is on, Roboze will be there to provide the most innovative solutions which are based on high thermoplastic materials.”

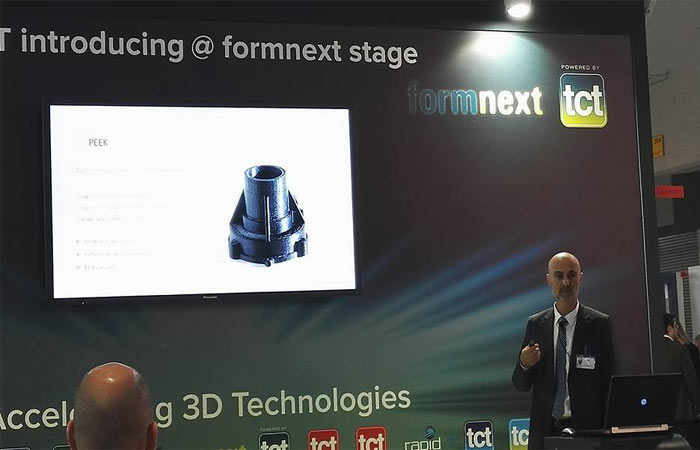

The last day the potential of this new solution was better explained by Gil Lavi, VP Global Sales & Business Development at the Formnext TCT stage event, where he shared the story of Roboze since it was established in 2013 and its solutions. Especially focused on the company’s beltless mechanical movement system that takes FFF quality, accuracy and repeatability to a whole different level, together with presenting a comparison with Mid and High-End FDM technology.

Furthermore, displaying real end use parts of advanced applications printed by Roboze unique techno-polymers materials, made by the company’s customers from Automotive, Medical, Aviation and more. After that the speech convert on explanation of capabilities of high thermoplastics with an interesting view of Roboze’s future, in term of material innovations.