Digital printing technologies provider Roland DG continues to support 3D sector. The company has released its 3D milling machine.

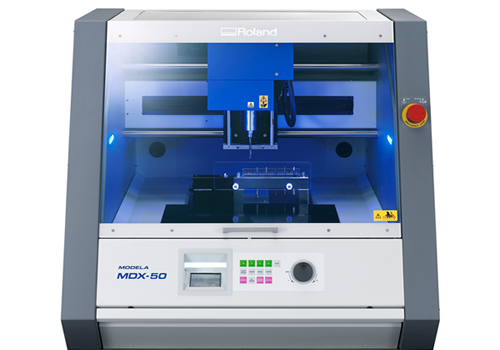

Launching its 3D monoFab series ARM-10 and SRM-20 at SIGN Istanbul 2015, Roland DG continues its 3D project this year as well. Contributing to the sector with resin manufacturing as well as printing machine, the firm presented its new milling machine MODELA MDX-50 last month.

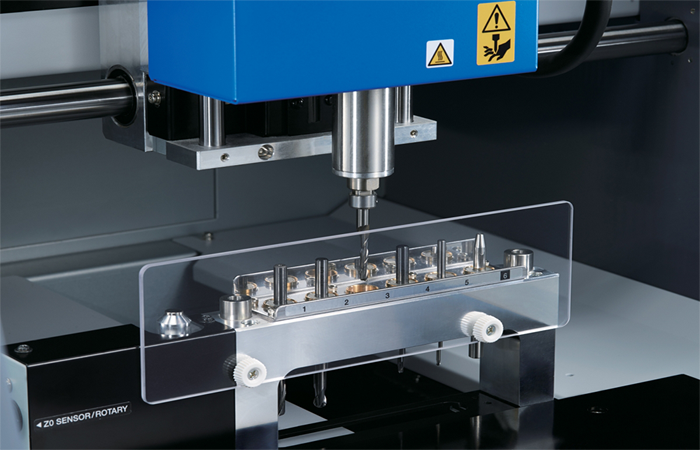

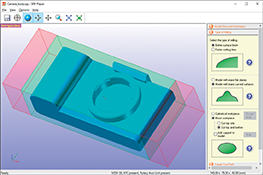

Offered as a complete system, the MDX-50 comes with easy-to-use CAM software and features a number of enhancements over Roland’s popular MDX-40A mill, including a larger workspace, an automatic tool changer (ATC), and faster milling speed.

“The MDX-50 takes desktop digital milling to the next level, incorporating advanced capabilities that increase overall performance and open up new creative opportunities for users,” said Matt Anderson, Roland DGA’s Product Manager, 3D Solutions. “That makes this innovative, value-packed machine ideal for handling a wide range of applications within both professional product design and educational settings.”

The MDX-50 boasts many of the same features that make the MDX-40A so popular, plus a number of improvements that allow for greater productivity and an easier, safer user experience. The machining area has been enlarged 60 percent to accommodate larger models

and mill multiple objects simultaneously. It’s also equipped with a standard Automatic Tool Changer (ATC) that further enhances productivity by reducing the time and effort required to replace tools. An optional rotary axis unit can rotate work materials 360 degrees for milling cylindrical objects and automating the fabrication of two-sided, four-sided and custom-angled items. Together, these advanced features ensure trouble-free, uninterrupted production.