Increasing 3D activities very rapidly, Russia continues successful productions. Presenting its first metal printer last July, the country now started to manufacture a 3D printed engine system with the contributions of Russian All-Russian Institute of Aviation Materials (VIAM) and FPI(Foundation for Advanced Research).

Russia has made important investments to 3D printing lately and now brings VIAM and FPI together to develop 3D printed engine. In the project the two partners will join froces to provide a more advantageous alternative for drone and aircrafts.

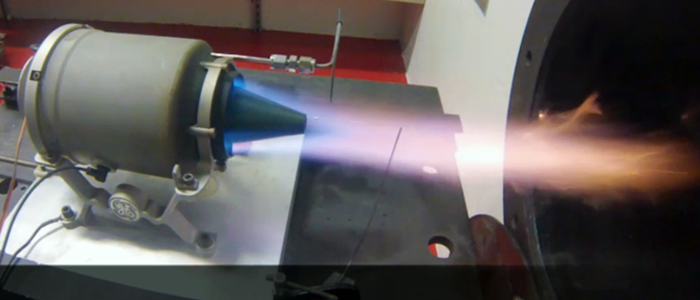

VIAM, in collaboration with the Russian defense industry FPI has announced it will be developing a drone that can be powered by a 3D printed engine that has also been developed by VIAM and which was unveiled last month. The small-scale engine is reportedly made entirely from 3D printed parts, weighs only 900 grams, and has a thrust of 75 kilograms. According to VIAM, the 3D printed engine’s thrust could also be increased by another 75kg with only a minimal increase in mass.

“The engine is made entirely on the basis of VIAM additive manufacturing using new laser sintering technology and metal powder mixes for heat-resistant and aluminium alloys, which have also been developed by the institute’s experts. We were able to print an engine with unique parameters impossible to achieve with conventional casting by using additive manufacture technology. For example, the thickness of the combustion chamber’s walls is 0.3 millimetres. Such parameters are only possible with 3D printing,” VIAM Director General

Evgeny Kablov stated.

VIAM and FPI will continue the 3D printing experiment and develop Russia’s additive manufacture sector, according to FPI deputy head Alexander Panfilov.”After the experiment, we will begin joint work on developing additive technologies in our country to broaden the range of materials as well as developing our own unique 3D printing stations,” Panfilov added.