Formed by two graduates of Stanford University, San Draw continues innovations. Developing ‘Full-coloured-Applicable-Multimaterial’ (FAM) 3D printer technology, the company has carried out another big project. The firm manufactured a silicone insole which is thought to be effective in medical applications.

Established by Michael Lu and Gary Chang, San Draw entered the sector with FAM  printerworking with silicone materials. Grabbing attention in both printer and material segment, the company developed a silicone based insole with 3D printing.

printerworking with silicone materials. Grabbing attention in both printer and material segment, the company developed a silicone based insole with 3D printing.

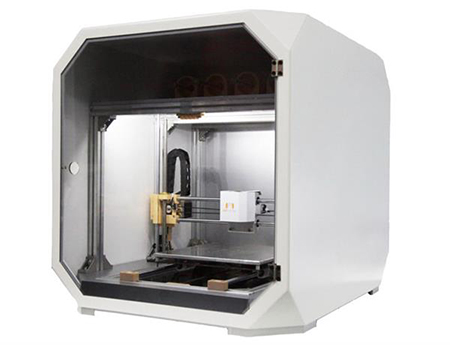

The 3D printed silicone insoles, which were each 3D printed in about five hours, are just one example of what San Draw’s FAM 3D printing system can produce. According to the young company, San Draw is promoting its services to a number of industries, including the footwear and medical sectors, as well as the automobile, consumer electronics, and construction industries. Their full-color, adjustable hardness, and multi-material 3D printer, which boasts a build volume of 300 x 200 x 150mm, has a layer thickness of between 0.05 and 0.2mm, and a print speed of 40 to 150mm in a second.

The insole is marked by two different colors: the yellow, which is made from a softer silicone, and the brown, which is a harder material composition. This product was made from a RoHS (Restriction of Hazardous Substances Directive) certified and halogen free silicone material. Additionally, unlike many other 3D printed insoles which require significant sanding and smoothing, the ones made with the FAM system do not require any post-processing and can be worn pretty much off the printer.