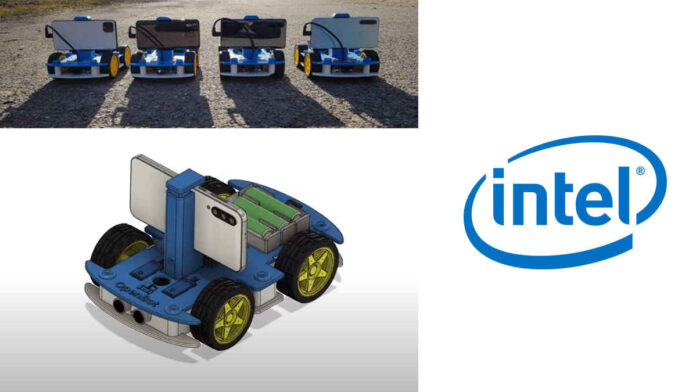

Openbot, developed by Matthias Müller and Vladlen Koltun in Intel labs, is an alternative to existing robots that are expensive or make significant compromises on sensory richness, computational power, and communication capabilities. Produced in accordance with Android smartphone standards, the cost of the vehicle decreases to $50 with additive manufacturing technology. The vehicle also includes state-of-the-art technological capabilities, thanks to the smartphone functioning as the brain of Openbot. In this way, Openbot supports advanced robotics workloads such as following individuals and real-time autonomous navigation in unstructured environments. Only 3 elements are required to have this robot; a smart phone, a 3D printing machine and $50.

Müller and Koltun equipped robots with extensive sensor suites, powerful computational abilities, state-of-the-art communication channels and access to a thriving software ecosystem. While doing this they used a smartphone. The team developed a software that allows smartphones to use this body consisting of 3D printed parts for mobile operation. Thus, the small electric vehicle designed at low cost forms the body of the Openbot, while the smartphone functions as its brain. Müller explained that their complete design and implementation, including all hardware blueprints and the software suite would be made freely available to support affordable robotics research and education at scale.

It only costs $50

Matthias Müller told that most related to their work is Wheelphone, where a smartphone is mounted on a robot for autonomous navigation. He continued his words by saying; “Unfortunately, this project is stale; the associated Github repos have only 1 and 4 stars and the latest contribution was several years ago. The robot has only two motors, a maximum speed of 30 cm/s, and is restricted to simple tasks such as following a black tape on the floor or obstacle avoidance on a tabletop”. Müller said that despite these drawbacks, it costs $250. Saying that their robot is more stale and can reach a maximum speed of 150 cm/s, Müller stated that it costs $35-50, and is capable of heavy robotic workloads such as autonomous navigation.

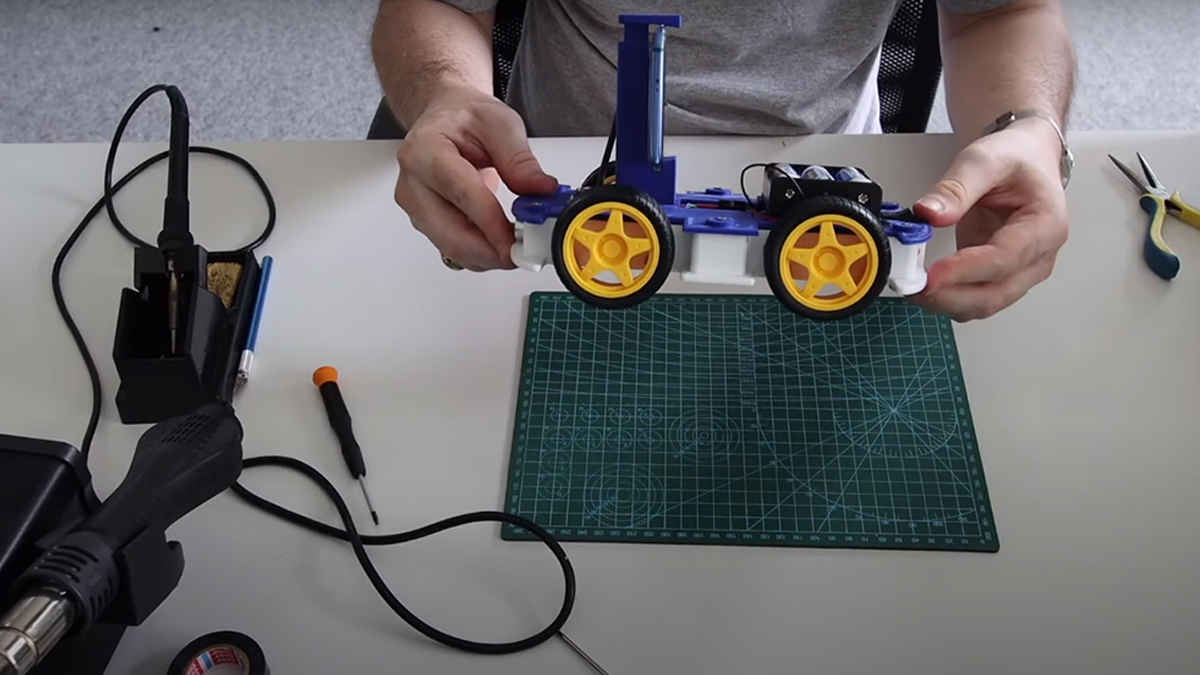

Complete production is 23 hours, assembly is 30-60 minutes

The robot body consists of several 3D printed parts. The bottom shell houses all the electronics; it is sealed by a top cover with a universal smartphone holder; which uses a spring to adjust to different phones. While assembly of the robot is easily done in as little as 30 to 60 minutes; only basic tools such as screwdrivers, pliers and a soldering iron are required for this job. Saying that in addition they had also designed a PCB (Printed Circuit Board) with integrated battery monitoring and two TI-DRV8871 motor drivers for increased efficiency, Matthias Müller noted that the PCB further reduces setup time and cost when building multiple robots. In this way, the assembly time is reduced to about 15 minutes. As the smartphone is connected to the robot, the smartphone’s capabilities are imparted to it.

With standard settings on a consumer 3D printer, such as Ultimaker S5; the complete print takes 13.5 hours for the bottom plate; and 9.5 hours for the top cover with the phone mount. In addition, it is possible to print at a faster pace with less accuracy. When using PLA as material, the weight is 146g for the bottom and 103g for the top. Considering an average PLA filament price of $20/kg, the total material cost is about $5.