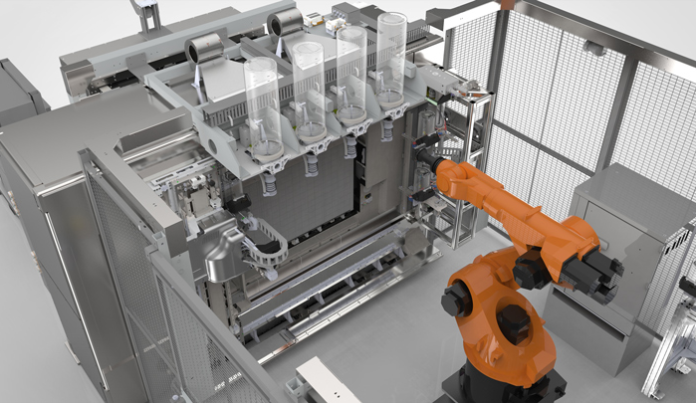

One of the market leader in industrial additive manufacturing, Stratasys continues to upgrade with its new technology Infinite-Build 3D Demonstrator. This printer developed especially for aviation, automotive and other heavy industry segments, offers a more flexible printing with vertical print platform and robotic body.

The company has collaborated with Boeing from aerospace and Ford from automotive sector to develop “Infinite-Build” technology, which can 3D print parts quickly, reliably, and on a larger scale than previously possible. Examples of the new capability would be an entire aircraft interior panel.

The new system works by turning the standard fused deposition modelling (FDM) technique literally 90 degrees on its side. By printing parts vertically and using gravitational supports and bonding techniques, it greatly expands the build volume in the horizontal plane.

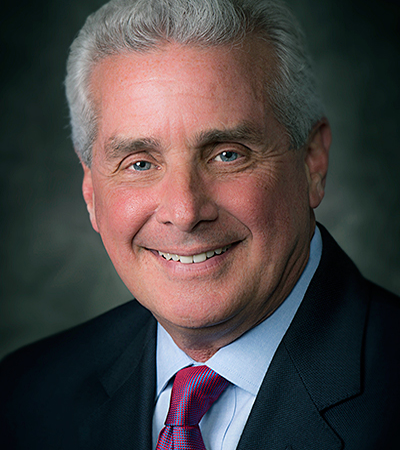

“Additive manufacturing represents a great opportunity for Boeing and our customers, so we made a strategic decision more than a decade ago to work closely with Stratasys on this technology. We are always looking for ways to reduce the cost and weight of aircraft structures, or reduce the time it takes to prototype and test new tools and products so we can provide them to customers in a more affordable and rapid manner. The Stratasys Infinite-Build 3D Demonstrator enables products to be made at a much larger and potentially unlimited length, offering us a breakthrough tool to add to our robust additive manufacturing processes,” said Darryl Davis, President, Boeing Phantom Works.