It wouldn’t be wrong to say that every technology is integrated in our daily lives after some time. 3D printing has become an accessible technology, too. Aside from that it is one of the rare technologies formed two different segments as industrial and personal use. That’s why this year works on 3D printing technology increased its speed. Focusing on during and after metal printing problems, Swanson School or Engineering started working for a smoother printing process.

The project called; “Novel Computational Approaches to Address Key Design Optimization Issues for Metal Additive Manufacturing,” is a three-year, $350,000 GOALI (Grant Opportunities for Academic Liaison with Industry) grant funded by the NSF’s Division of Civil, Mechanical and Manufacturing Innovation (CMMI). The team, based in the Swanson School’s Department of Mechanical Engineering and Materials Science, includes Associate Professor and Principal Investigator Albert To; and co-PIs Assistant Professor Sangyeop Lee and Adjunct Associate Professor Stephen Ludwick. Aerotech, Inc. will partner with Pitt by providing designs and evaluation. The group’s research is an extension of previous funding from the Research for Advanced Manufacturing in Pennsylvania program (RAMP).

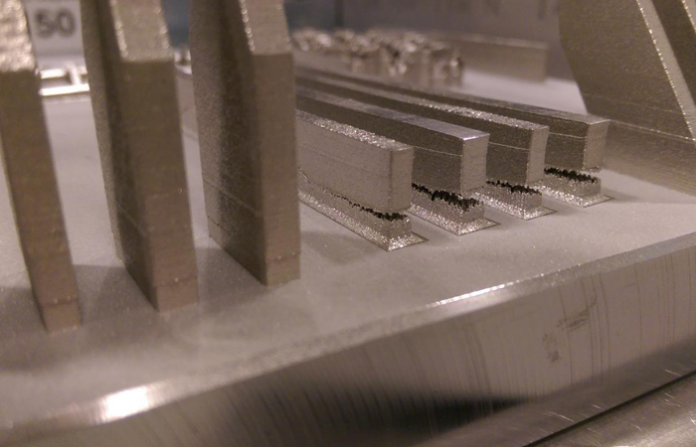

“The ability to create geometrically complex shapes through additive manufacturing is both a tremendous benefit and a significant challenge,” Dr. To said. “Optimizing the design to compensate for residual distortion, residual stress, and post-machining requirements can take days or even months for these parts.”

To mitigate these challenges, Dr. To and his group will first develop a simple yet accurate thermomechanics model to predict residual stress and distortion in an AM part. Next, they will develop a topology optimization method capable of generating designs with both free-form surfaces and machining-friendly surfaces. According to Dr. To, this will compensate for the geometric complexity and organic nature of AM parts, which contribute to their potential for distortion and post-machining problems. These approaches will then be developed and tested using real parts and design requirements provided by Aerotech.

The University of Pittsburgh’s Swanson School of Engineering is one of the oldest engineeringprograms in the United States and is consistently ranked among the top 50 engineering programs nationally. The Swanson School has excelled in basic and applied research during the past decade and is on the forefront of 21st-century technology including sustainability, energy systems, bioengineering, micro- and nanosystems, computational modeling, and advanced materials development.