While technology makes lives easier in many ways and 3D printing support that. This technology entering many segments from health to fashion, contributes sportsmen as well. Attending to MotoGP FIM CEV European Championship held in Barcelona last month, French race team The Perigueux gained advantage with its car including 3D printed parts.

At MotoGP FIM CEV European Championship event in Barcelona, one of the winning motorcycles featured the metal 3D printing brand Renishaw on its body design. Well, if you were wondering whether 3D printing helped in the making of the impressive vehicle the answer is yes, as Moto2 team TransFIORmers, who were responsible for the motorcycle in question, teamed up with French metal 3D printing experts I3D Concept for its construction.

TransFIORmers is led by former 250cc World Championship rider Christian Boudinot, and the team’s unconventional suspension system was inspired by the seminal work of the legendary French motorbike designer Claude Fior.

“To improve overall motorcycle performance, reducing the weight of all components located behind the shock absorbers is absolutely vital,” explained Jérôme Aldeguer, Mechanical Engineer at TransFIORmers. “Failure to optimise component weights can have an adverse effect on vibration, braking and acceleration, so weight reduction is a really high priority.”

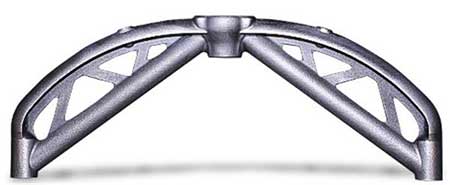

Before 3D printing the part, the TransFIORmers team handcrafted a version of it out of steel, which necessitated the assembly and welding together of twelve separate parts. Not only was this process more time consuming, but it resulted in a part that was unnecessarily heavy. With I3D Concept’s metal 3D printing technology and know-how, they were able to reproduce the part in a single print and using a lightweight and strong titanium metal, Ti6AI4V. The result was a part with a reduced weight of 40%, making for a weight saving of 600g.